CAD Design Complete!

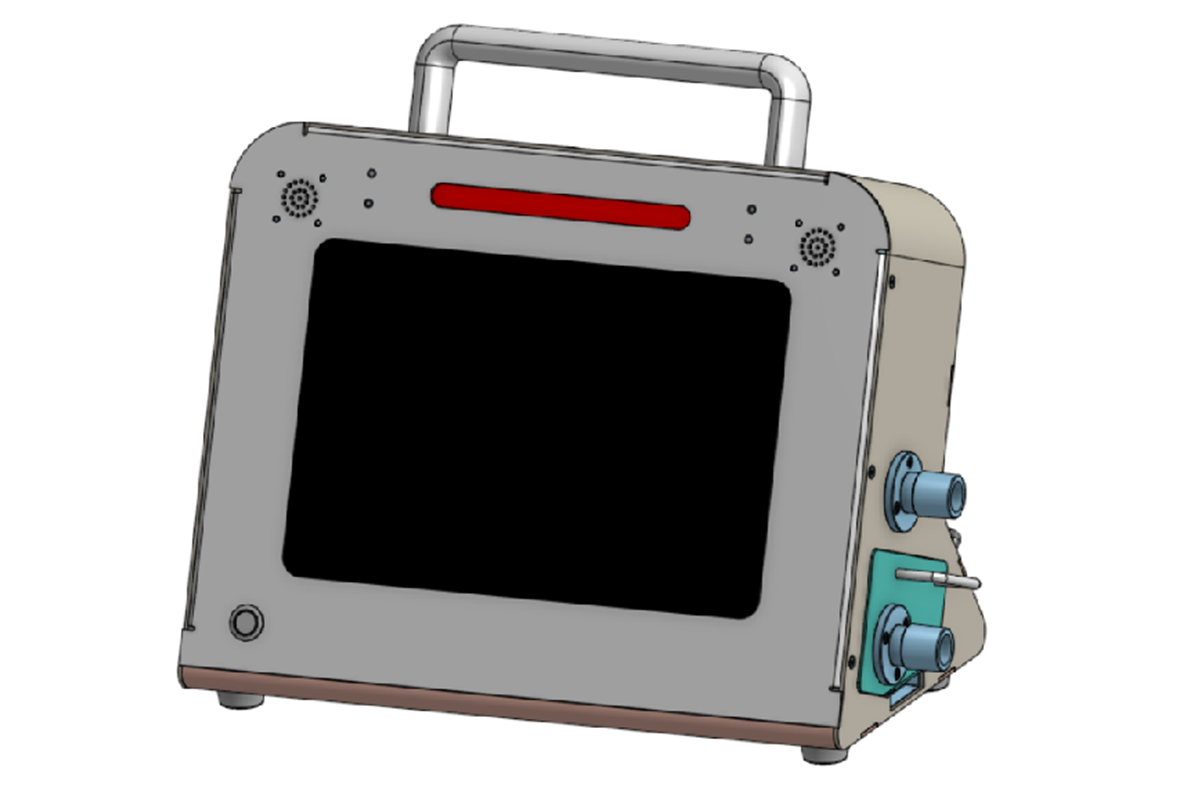

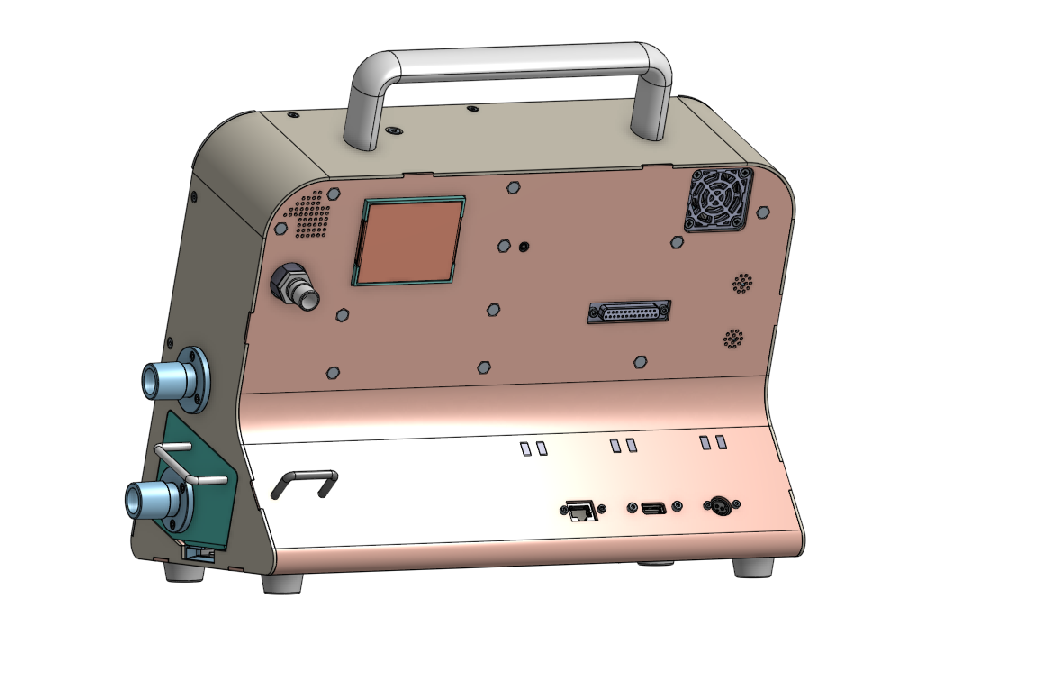

Hello Project RED supporters! Apologies that we have not issued a project update in a while, but we have been very busy with ventilator development! And a lot has happened in the past three months. After three months of close work with our friends at Paaila Technology, we have finished the complete mechanical CAD design of the RED-1 ventilator. Below are some pictures showing the external and internal appearance of the ventilator. We were able to achieve an appearance and style very similar to the concept drawing we started with. We have also partnered with a manufacturing company in China (HLH Prototypes) who will be making the first ventilator prototypes for us based on this design. We've already released parts to them to start producing the first few ventilators.

(For a more detailed walk through the internals of the ventilator, jump ahead to the next section)

In August, we built three new bench-top ventilator systems for use in software development. A picture of the three systems, and a video of one of them up and running, are below.

Also, software development is going extremely well. We worked closely with ICS to come up with a flexible, extensible communication protocol between the ventilator microprocessor and the GUI processor. This protocol allows us to easily re-configure the GUI design to accommodate new modes of ventilation in the future. Initially, we plan to implement Pressure Control Ventilation (PCV) and Pressure Regulated Volume Control (PRVC) modes, but soon after we plan to deploy additional modes such as PSV and SIMV. A video of our GUI, running and plotting real data gathered from one of our prototypes, is below:

By November we expect to have several fully functional ventilators running in the actual ventilator enclosure!

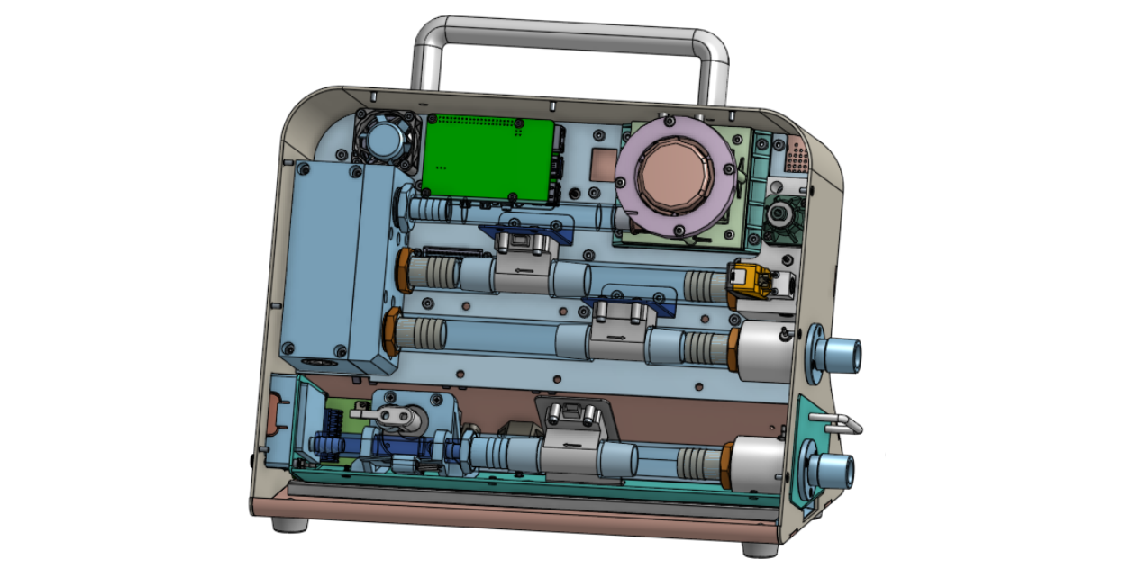

Ventilator Design Walkthrough

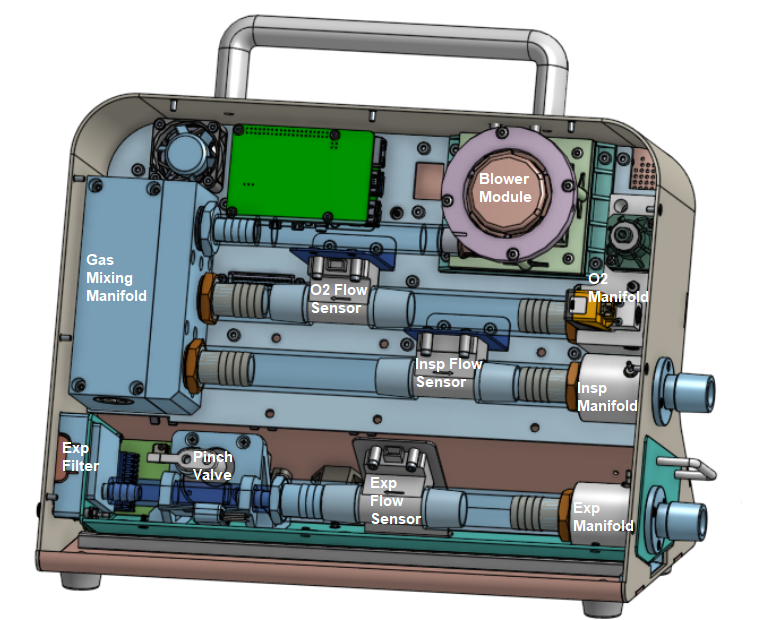

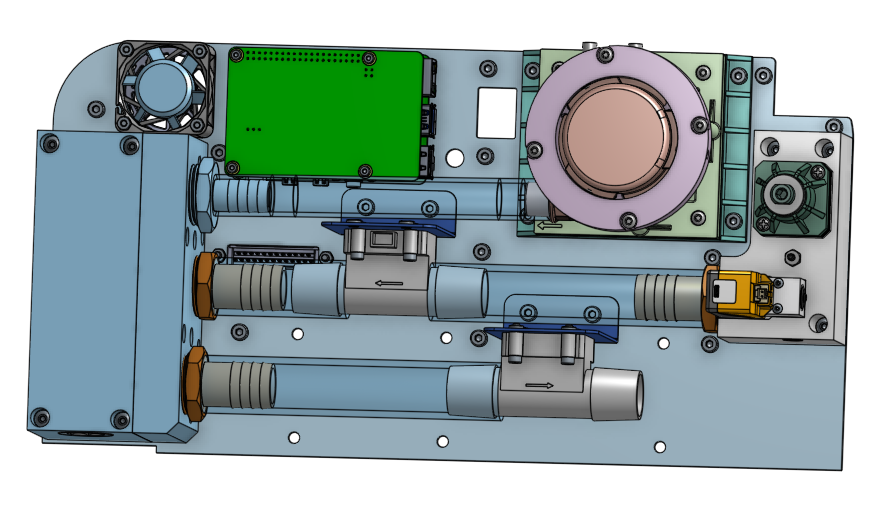

We developed the mechanical internals of the ventilator in a modular fashion. There are custom blocks to handle specific functions, such as air filtering, O2 metering, gas mixing, safety valves, etc. We also focused heavily on ease-of-manufacturing. The major components of the design are shown below:

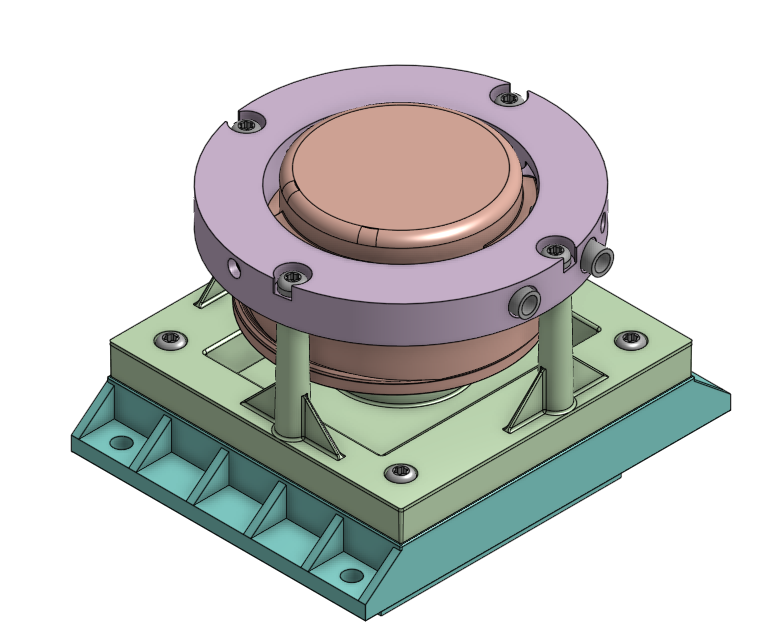

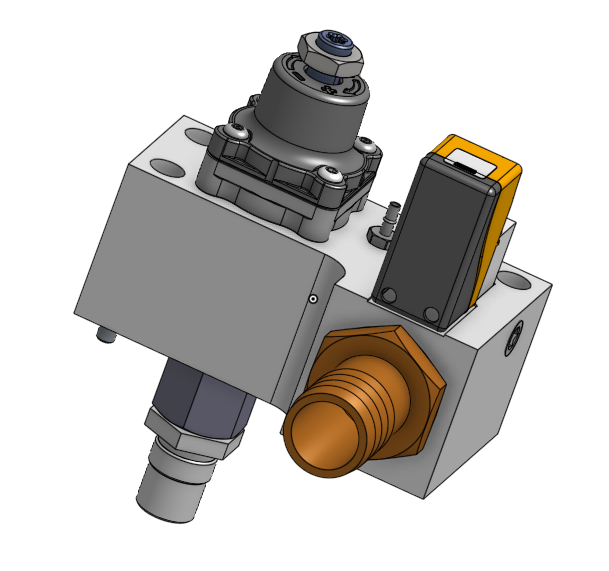

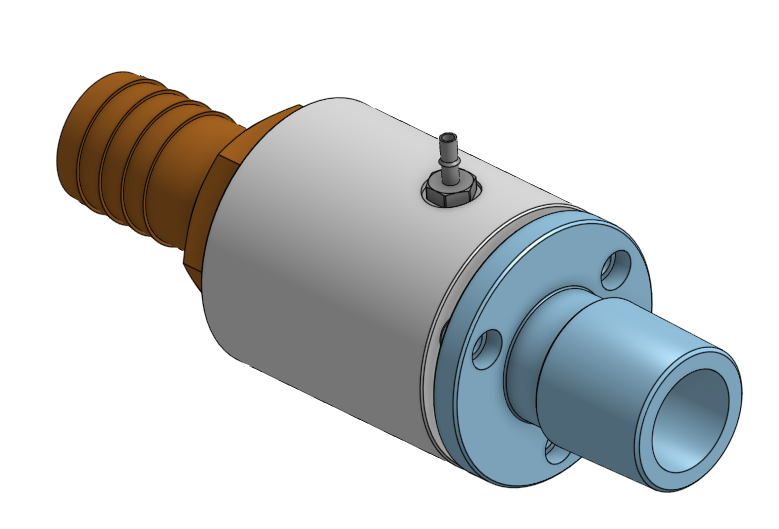

The Blower Module, O2 Manifold, Gas Mixing Manifold, Insp Manifold, and Exp Manifold are all custom sub-assemblies designed by Project RED engineers. Some closer views of these design blocks are provided below.

We placed a lot of thought into making the ventilator easy to build. A key feature in this regard is that all of the Inspiratory components are located on a removable metal “tray”:

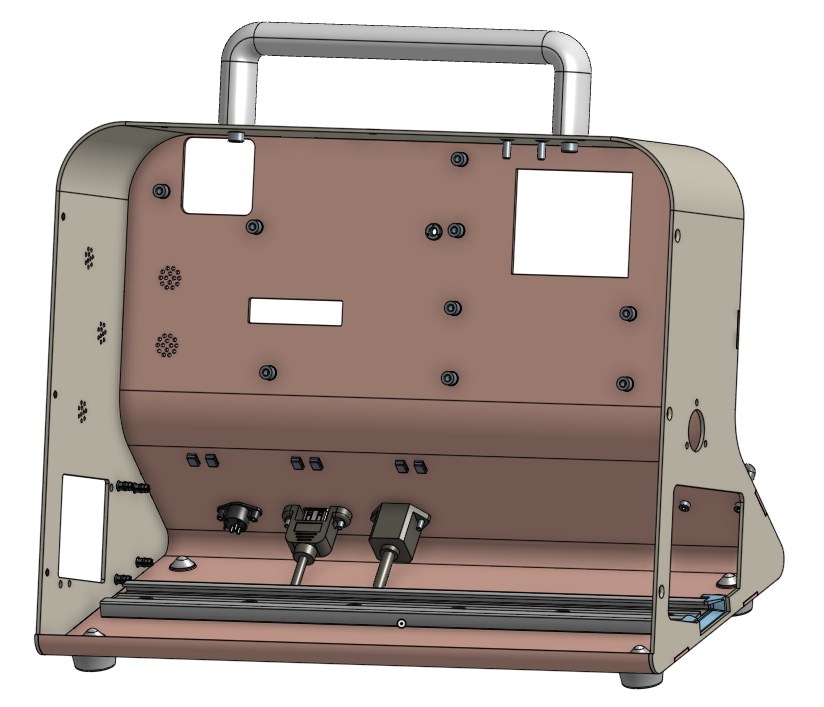

The tray has pressed-in (PEM) nuts and standoffs, so a technician can simply screw down the sub-modules to the tray, attach tubes and clamps, and then drop the tray into the enclosure shell. The enclosure shell also has pressed-in standoffs for accepting the tray. The enclosure shell is made of 2mm thick aluminum sheet metal, bent and seam-welded together, so it should be extremely rugged. The enclosure is shown below:

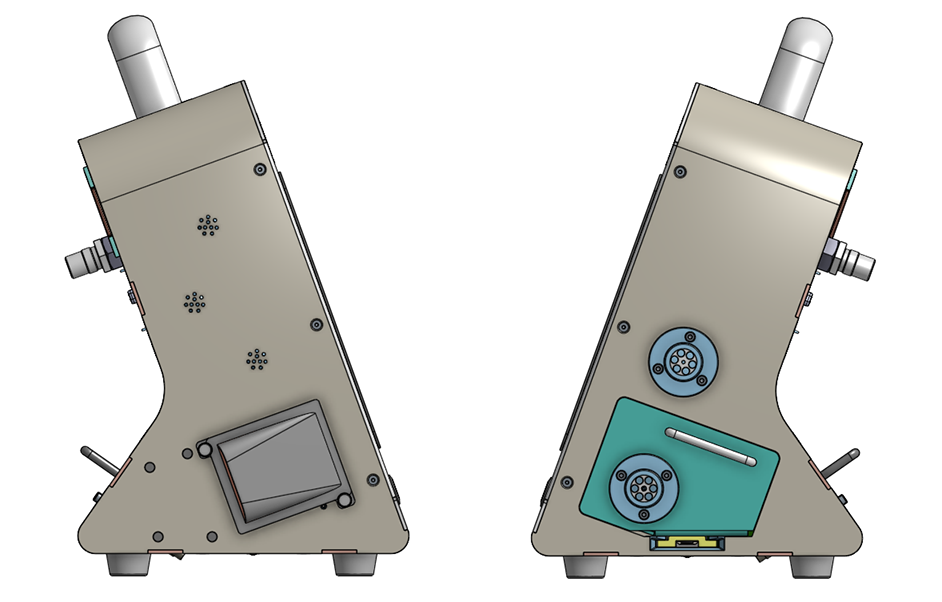

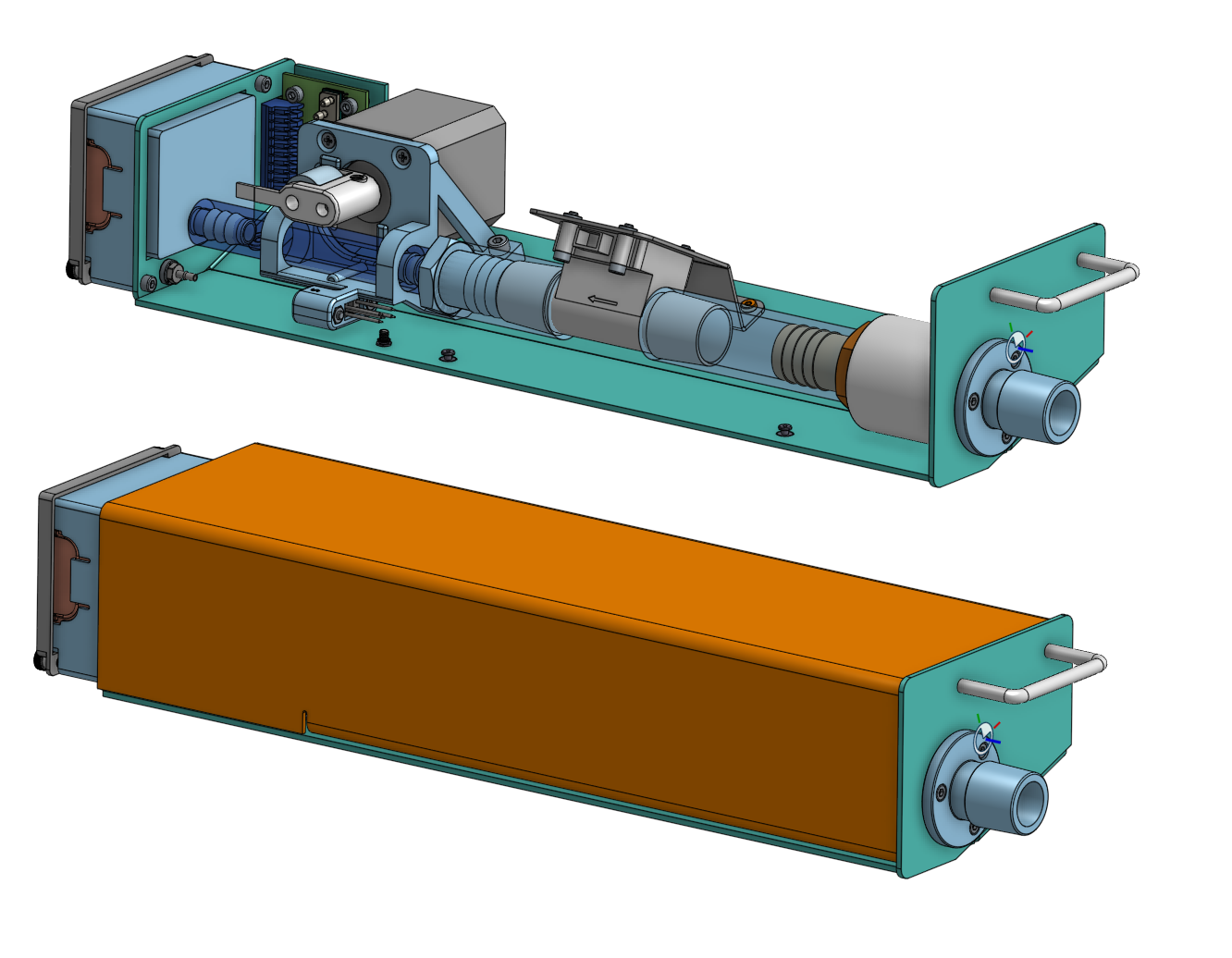

Another important feature of the design is the “Expiratory Cartridge.” The Expiratory cartridge handles all exhaled gas from a patient, and lives on a sliding rail so it can be removed from the ventilator. This is because exhaled gas from the patient may be contaminated; therefore, it is good practice to keep the expiratory circuits isolated from the inspiratory circuits, to prevent contamination of the ventilator. (Normally an external bacterial/viral filter should also be used on the expiratory limb of the patient circuit). All expired gases are contained within tubing inside the Expiratory cartridge, and then filtered again before leaving the cartridge. In case there are small leaks within the tubing in the cartridge, there is a sheet metal cover for the cartridge which greatly reduces the risk of contaminants entering the upper part of the ventilator. For decontamination purposes, the cartridge can be detached from the ventilator and sent for cleaning. Since the Expiratory cartridge has electronics on it, we had to develop a solution for mating/de-mating an electronic connector when the cartridge was inserted or removed. Maintaining alignment of the connector halves was a tricky problem, but we believe we have a solution that will work, and we will be testing it when the first prototype units come back next month. The Expiratory cartridge is shown (both with and without cover) below.

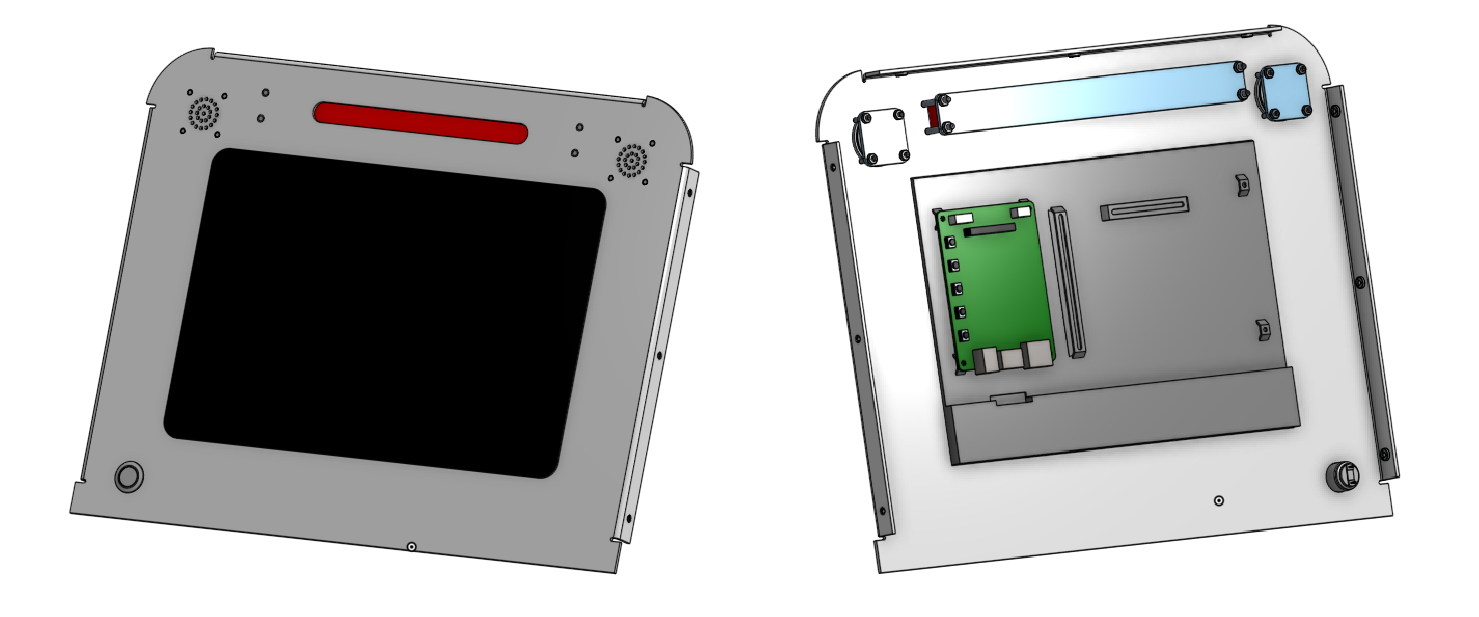

Finally, there is a simple subassembly for the front-cover, which consists of sheet metal, two speakers, an LED light bar, the LCD touchscreen, and some simple brackets:

All in all we are very pleased with how the design has turned out, and we can’t wait to test the first few units in November. The best news, perhaps, is that after pricing out most of the custom mechanical parts, we are quite confident that this ventilator can be built for well under $4000 USD, even at relatively small quantities (100 units or less) !